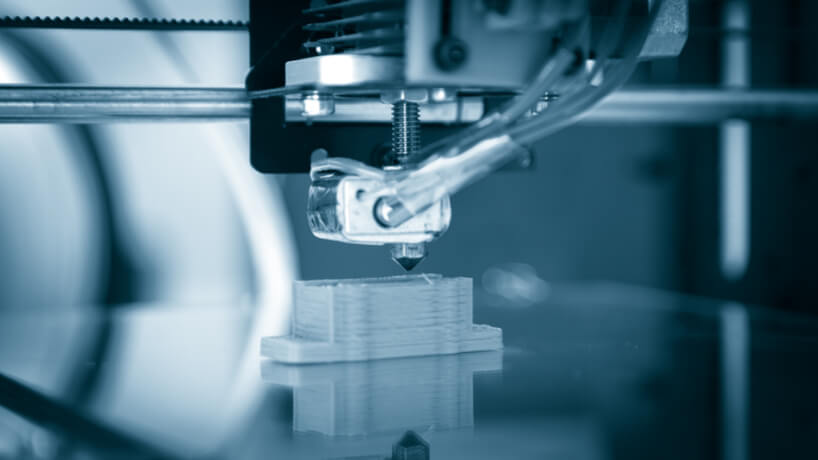

When Michelle Crowley, PCMA’s senior director of global strategy, returned from the Dubai Association Conference at the end of 2017, she shared one of the city’s most impressive architectural achievements: the first-ever, fully, 3D-printed office building. Appropriately named The Office of the Future, construction workers built the structure in just 17 days. The project poses a question for the events industry: Could 3D printing revolutionize the way convention centers come to life?

Adam Paulitsch, AIA, NCARB, designer and associate principal at Populous — who has worked on designs for renovations and expansions at the Henry B. Gonzalez Convention Center in San Antonio, the Anaheim Convention Center, and a number of other major convention venues — says that 3D printing isn’t some far-off-futuristic element. He’s already been using it to shape the early phases of those buildings and other convention center projects.

“From a purely architectural perspective, 3D printing is slowly becoming the standard for the design process,” Paulitsch said. “In school, you’re taught about building models and prototyping, but I would say that approximately 90 percent of the models we build use 3D printing.”

Paulitsch said that Populous used to have a model shop that built scale models, and the process could take up to two months to finish one project and cost anywhere between $20,000 and $50,000. “Now, you can produce something of similar quality with a four- or five-day turnaround for one-tenth of the cost,” Paulitsch said. “There is no more efficient way of building a model to help a client envision the real thing.”

What about the actual building process? Paulitsch said that there are plenty of reasons that 3D printing can move from miniature models to the big time. “It’s an economy of scale where there is already such incentive for us as architects to design within a set of pre-fabricated guidelines,” Paulitsch said. “You’re already seeing it in residential building now where parts are pre-fabricated off-site and then delivered to the job site. When you look at something like the Dubai Office of the Future, it’s easy to see something like that shaping up for the smaller components of a convention-center space.”

The Challenges of Being Cost-Effective

It may be easy to see, but Paulitsch recognizes that it will be more challenging to actually do. “Creating change in the meetings industry can sometimes feeling turning a cruise ship,” Paulitsch said. “Reinventing the way that these centers are built will include some steep challenges.”

The minds behind the Dubai Office of the Future were happy to promote that they managed to reduce labor fees by 50 percent. In a convention industry that aims to showcase its role in job creation, statistics about overall wage decreases will not create the kind of headlines that speak to policymakers. “These buildings are expected to last between 40 and 50 years, minimum,” Paulitsch said. “There is such a high cost to build them, and one of the leveraging components to securing approval is often the amount of jobs the project will create for the community.”

While there may be a more efficient way to build, he said, labor unions and businesses that put money back into the economy need to be taken into consideration. “Sometimes, there might be four to eight different government organizations involved in the decisions,” he said, “and officials might elect to move forward in a more expensive manner.”

For now, perhaps new convention centers can consider taking baby steps into the world of 3D printing. “Imagine a new convention center that isn’t a complete shift from the current construction approach,” Paulitsch said. “There could be an opportunity to designate a portion of the building that will get reprinted every three to five years to respond to changes in the industry and new preferences for learning and interacting.”

This kind of compromise between job creation and flexibility makes sense, since centers are supposed to last for five decades, and yet human behavior is changing at a much faster pace.

“We’ve been spending a lot of time on what the next generation is going to think of these facilities,” Paulitsch said. “We’re trying to think about Generation Z, and we are entering a phase of mass customization. Every single person expects the experience to be 100 percent for them. Now, when people go to conferences, they want an Uber just for them. They want the hotel concierge to know their name. They want content specific to their needs. That’s all easier to accomplish in a digital world.”

By overlaying a 3D printing concept with mass customization, Paulitsch said, “you could have a custom physical experience as well. Imagine when the second you register for a conference, the 3D printer starts to create a custom physical space.”

That type of user experience will not happen tomorrow, but Paulitsch emphasized that there are immediate opportunities to leverage the efficiency of the technology. “Think about the utensils that attendees use to eat at meals, the benches in the concourse, or the desks in a room,” he said. “I think there is a market to 3D print some of the items inside a convention center right now.”